The Deming cycle is a sequential algorithm of actions created to improve the efficiency of work processes and prevent possible risks. If you want to keep your work processes under control, react quickly to changes and make strong—willed and difficult decisions - you are in the right place.

The method appeared thanks to the American economist Walter Shuhart. Part of his work, by the way, formed the basis of another methodology for managing and optimizing processes — 6 sigma.

Shuhart came up with a three-stage quality improvement cycle: planning-action-verification. Later, the method was refined by the American scientist William Deming and added another stage — correction or work on errors. Therefore, most often the method is named after Deming (although sometimes it is called the "Shewhart-Deming cycle").

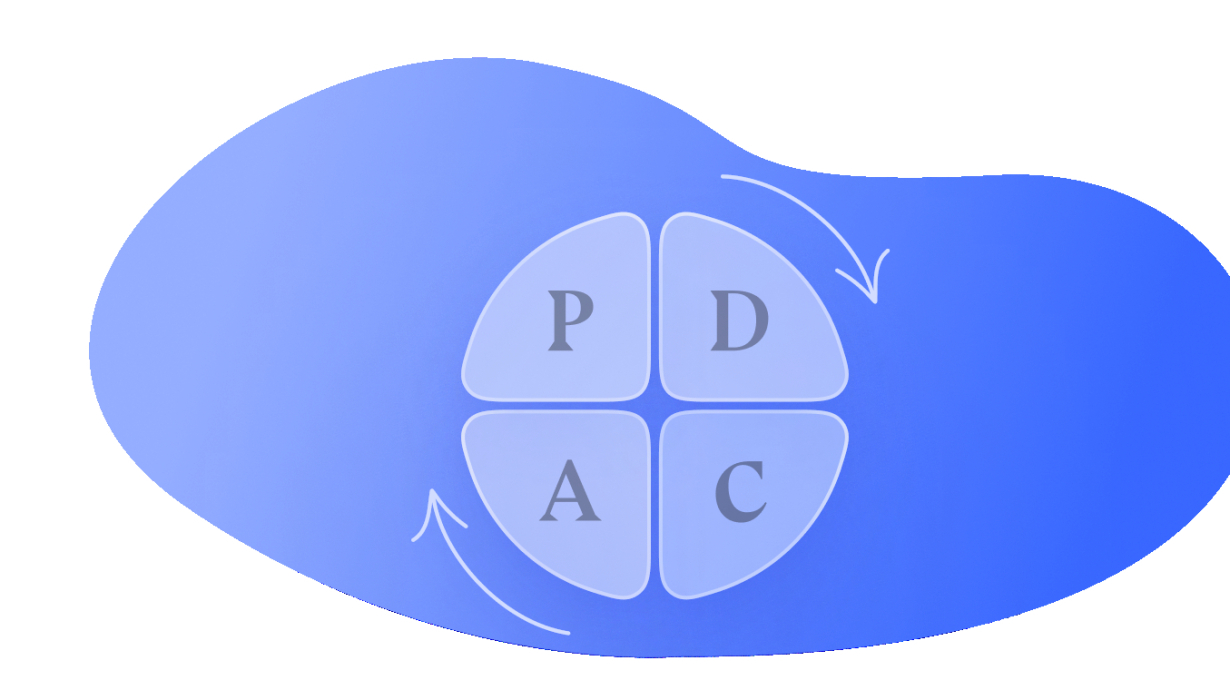

What is the Deming cycle

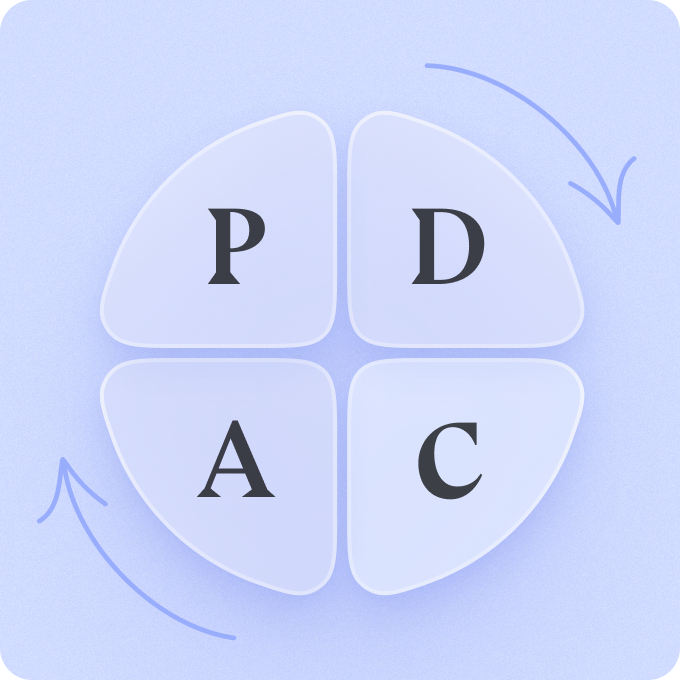

So, the Deming cycle is a cyclic algorithm consisting of four steps. According to the first letters of the steps, it is also called PDCA. Sometimes the name of the third stage is changed, and PDCA turns into PDSA, but we will focus on the most popular — the first option.

Plan a solution, prepare for possible problems. At this stage. Literally — you make a plan for the period, assess the risks, etc.

- Do (Do) — you implement the plan.

- Check (Check) or Analyze (Study) the results of this cycle. Make sure everything goes according to plan, or something goes beyond it. Find problem areas, etc.

- Correct (Act) — if everything worked out within this cycle, then here you decide which innovations to try in the next one. And if there were problems, you start the next cycle, only taking into account the errors.

How to apply the method in practice

Imagine, you launched an advertising campaign in social networks, estimated the expected conversion, the number of clicks, sales, etc. But in fact, the advertisement did not collect even half of the expected response and failed. And you've already spent the budget and time.

But what would happen if you approached the launch of advertising using a PDCA cycle:

- Planning. Preparation for the launch of advertising begins with a thorough analysis: audience and needs, USP, etc., as well as planning the results. Then generation of hypotheses, creation of creatives, copywriting and competent installation of KPIs.

- Realization. Now we are launching advertising — the main thing is to keep your finger on the pulse to control possible deviations from the plan and expectations.

- Check. Don't forget to analyze the intermediate results, not just the final ones. For example, after a day or two, check the results of the campaign and estimate what prospects it has.

- Adjustment. After analyzing the results, decide what to do next. Continue or pause, assemble a brainstorm team and analyze what went wrong, make edits to improve performance, etc.

And again and again…

Advantages of the Deming Cycle

The iterative approach to optimization has not so many disadvantages — except that it takes time. But there are much more advantages:

- It is easier to make decisions, because all possible results have already been analyzed. Just choose what will be more useful for the company.

- It is easier to identify weaknesses and eliminate them, since the processes of working on the product are analyzed at the planning stage. Then you notice if there are deviations somewhere that are not critical yet. And this helps to optimize business processes.

- The situation is under control, because intermediate results are monitored — the work processes are stable, there are no unforeseen cases.

- The workflow and employees are more productive, because the result is monitored and problems are identified in time (the main thing is not to track the work on errors, bringing micromanagement).

- Minimization of problems and risks in the future.

So, the Deming cycle or PDCA cycle is an iterative approach to working on tasks that helps to analyze possible risks, monitor workflows and adjust them without letting the situation take its course. The main thing is to remember that PDCA cannot end — as soon as one cycle is over, another begins. Because there is no limit to perfection, and the indicators of your project can always be even better.