I heard a lot about the Theory of Constraints (TOC) by Eliyahu Goldratt, but I never really got into it. In principle, I am not the only one - unlike Agile and similar “fashionable things”, TOC is not very popular in our country. Some companies use this management methodology (and quite successfully), but do not talk about it publicly, because they take the theory of constraints for granted. And if you look… it really is.

The essence of the theory of constraints

TOC proposes to consider a company as a chain of interrelated processes, and to consider that its overall efficiency is influenced not only by individual links, but also by the links between them. The chain analogy is not just that. Just as a metal chain can have a weak link that reduces the reliability of the entire chain, so can a company have an inefficient process that reduces the efficiency of the entire system.

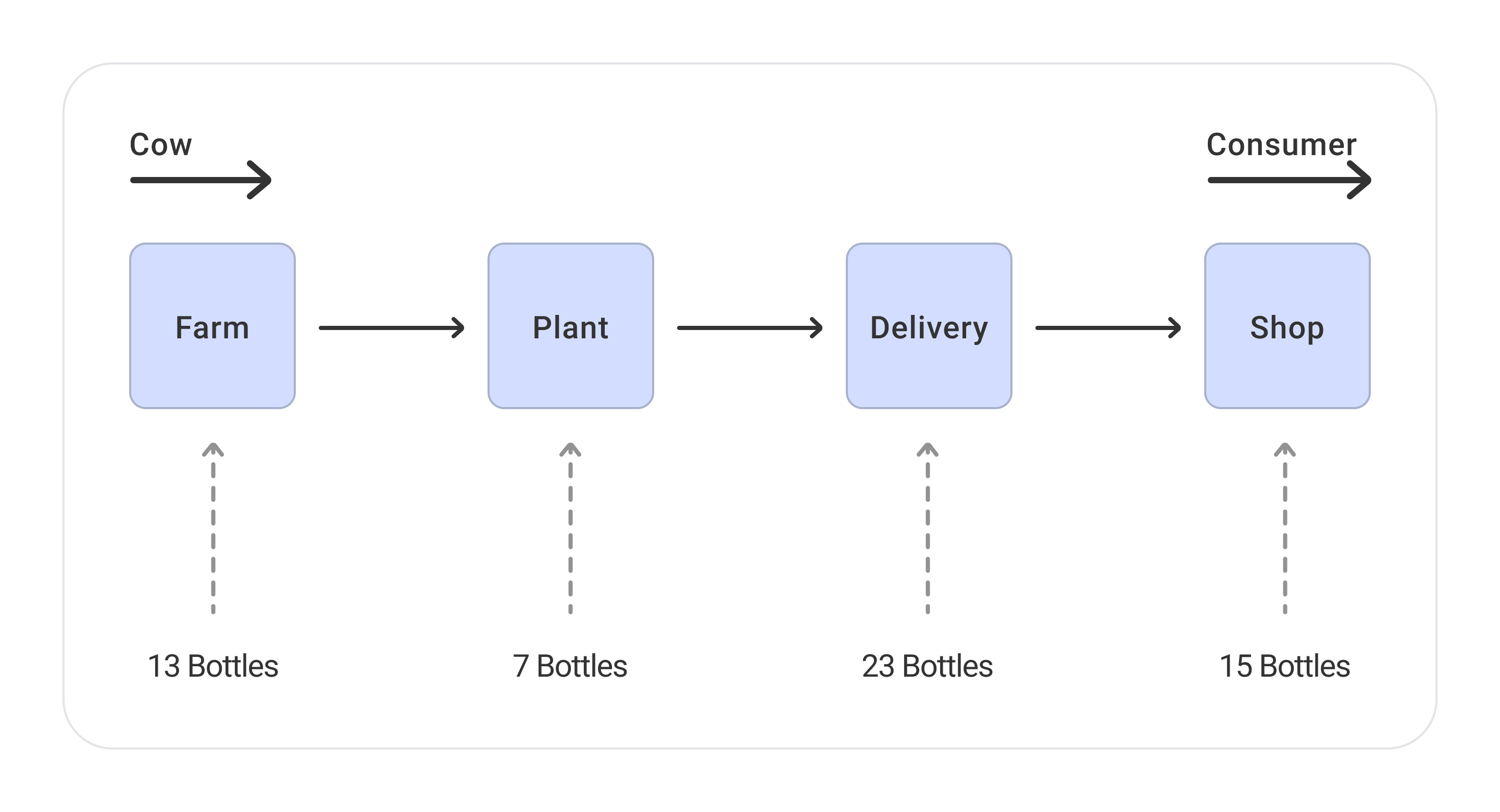

It's easiest to understand with an example. Imagine the supply chain of milk to stores (I don't guarantee that it is plausible in my example, but, as they say, "this is how I see it"). First, milk is extracted on the farm, then sent to the factory, where it is sterilized and packaged in containers. Next, the milk is sent with the help of a logistics company to a store where it is sold to end consumers. Let's say each stage has its own throughput - how many bottles of milk can pass through the stage in a period of time:

- the farm can produce 13 bottles per day,

- factory can produce 7 bottles per day,

- the logistics company's car park allows transporting 23 bottles per day at once,

- and the demand in the store is sufficient to sell 15 bottles a day.

But the question is: how many bottles of milk per day will the store actually sell? That's right, 7 pieces. The real efficiency of the logistics service and the store will be equal to the efficiency of the plant, despite their potentially high throughput. Briefly speaking:

The effectiveness of the entire chain is equal to the effectiveness of its weakest link.

In my example, a factory is a bottleneck, a bottleneck that slows down the entire supply chain. But at the same time, it is a point of growth.

The growth of the company is always limited by something, this is normal. There may be several restrictions, but at the moment only one affects the system the most. Finding it and eliminating it is your main task if you want to optimize processes and accelerate growth. The worst thing you can do here is to start working on all the restrictions at once. This will lead to nothing and will only burn resources. Instead, focus on the one constraint that holds the company back the most.

Types of restrictions

There can be very, very many restrictions that can prevent a company from achieving its goals. But there are several classifications that help to quickly cover everything. For example, it is very popular to divide restrictions into:

- power limitation - when it is clearly impossible to produce the desired result in the allotted time (the dairy from my example);

- time limit - when a company cannot make decisions quickly and adapt to the market;

- market restriction - when demand is not enough for the development of the company;

- paradigm limitation - when company employees have come up with something for themselves, and now it interferes with effective work;

- physical constraint - again going back to the milk production example, this could be a problem with a lack of machines from a logistics company;

- restriction of the company's policy - when the company has certain regulations that hinder the growth of production efficiency (for example, when you need to load it 100% to send a car from the factory to the store);

- sales department limitation - when any difficulties in the sales process can lead to their reduction.

But personally, I prefer to divide the restrictions on two grounds:

- materiality: material constraints - any lack of resources: money, people, equipment, etc.; non-material constraints - lack of demand and knowledge, difficulties in legislation or company policy;

- production system: internal restrictions - the company produces less than the market requires (the problem may be in poor equipment, lack of people, etc.); external restrictions - the company produces more than the market requires.

How to manage through restrictions

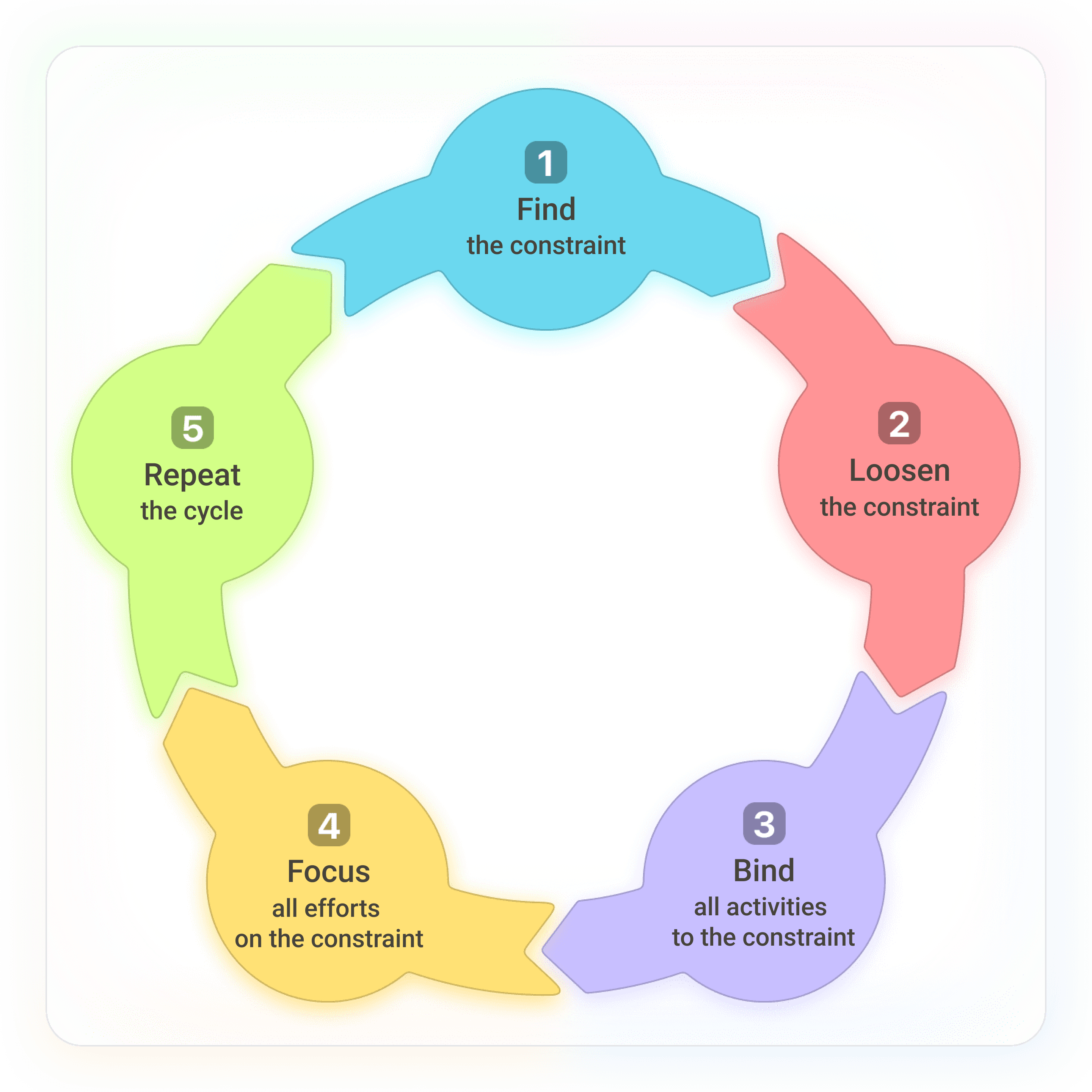

The Theory of Constraints is a management methodology, which means that it can be used to manage company processes, optimize them in order to increase efficiency. To do this, follow five consecutive steps.

1. Find the limit. If this is not done, all further actions will not make sense. For starters, it’s helpful and simple to ask yourself questions like “Where is the bottleneck in the workflow chain?” (it just sounds silly, but we don't really think about it often).

2. Loosen the constraint. Before you go to great lengths to eliminate the constraint, try to loosen it—for example, to improve performance in some way with minimal cost. If the constraint cannot be eliminated in this way, at least you will understand how, in principle, you can weaken its impact on the work of the entire company.

3. Bind all activities to the constraint. Check if all activities are associated with the found key constraint (I remind you that it can be only one at a time). If something is not connected, try to create this connection. The fact is that in most companies, not all processes are associated with a constraint - many of them exist simply because we think that they "will play a role in the future." The main point is to leave only the processes associated with the restriction - then the increase in efficiency after its elimination will be maximum.

4. Focus on eliminating the limitation. If after all the previous steps the restriction has not decreased and has not disappeared, you need to direct all resources to this. Experiment and try new tactics until you get rid of the limitation. This may require additional investments and significant changes in the company, up to a change in the business model.

5. Repeat. This stage is very conditional - it is needed only to emphasize the cyclical nature of work on TOC. So, once you've dealt with one constraint, you'll need to find the next one that's holding the company back. Constant introspection is an important part of the Theory of Constraints.

Don't be scattered, focus on the key constraints that prevent the company from working as efficiently as possible. By consistently eliminating bottlenecks, you can multiply the performance of the entire system as a whole in a short time. To do this, follow the five-step cycle I described above.